STREICHER is a global leading company based in Deggendorf, Germany, which specialises in the planning and construction of onshore and offshore drilling rigs according to specific applications and client requirements.

Additionally, STREICHER provides a wide range of drilling equipment and services, including hydraulic top drives, BOP closing units and BOP recertification.

Offshore rig technology for the oil and gas industry

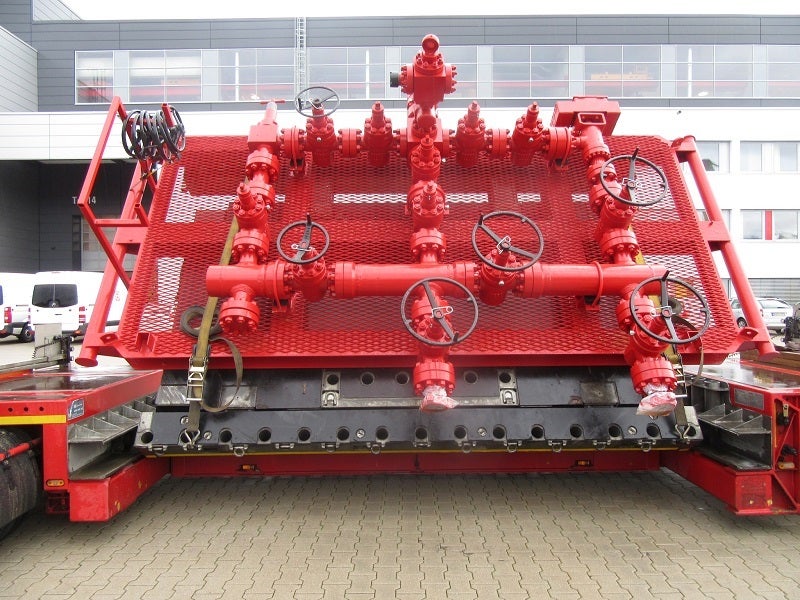

STREICHER offshore drilling rigs are customised for special applications and specific client needs. The technology solution can be used when a jack-up or refurbishment of the existing derrick is technically not feasible or economically viable. STREICHER was the first company that introduced the modular drilling rig (MDR) technology to the offshore sector.

The MDR technology strips down an offshore drilling rig into small lightweight modules. The modules can be easily transported by supply vessels and rigged up quickly at almost all fixed platforms, which have previously used a derrick. The VDD 400 series provides field-proven technology, which has been operating around the world, including the North Sea and Pacific Ocean. Besides the MDR technology, STREICHER provides automated light workover units (unit weight below 100mt) technology that can be used on jack-up rigs plugging and abandoning (P&A) operations, as well as on wellhead platforms for ESP replacements.

In addition to European and American standards, our offshore rigs comply with demanding NORSOK standards.

Repair and maintenance work for all of our offshore drilling rigs and equipment

Following the delivery of newly built drilling rigs, our aftermarket service team continues to provide clients with support services built on more than 15 years of experience and technical expertise. Our team is available through our 24-hour hotline.

STREICHER’s team provides complete turnkey solutions, as well as individual components for upgrading or building drilling rigs, including hydraulic top drives and pipe-handling systems.

We carry out repair and maintenance work for all of our offshore drilling rigs and equipment, with a specialist focus on upgrading existing rigs by incorporating the latest drilling technology and making revisions to ensure compliance with necessary standards, including the more stringent Norwegian petroleum industry requirements.

The STREICHER service centre in Deggendorf, Germany, has production and development capacities in departments such as hydraulics, pneumatics, piping, steel construction and electronics.

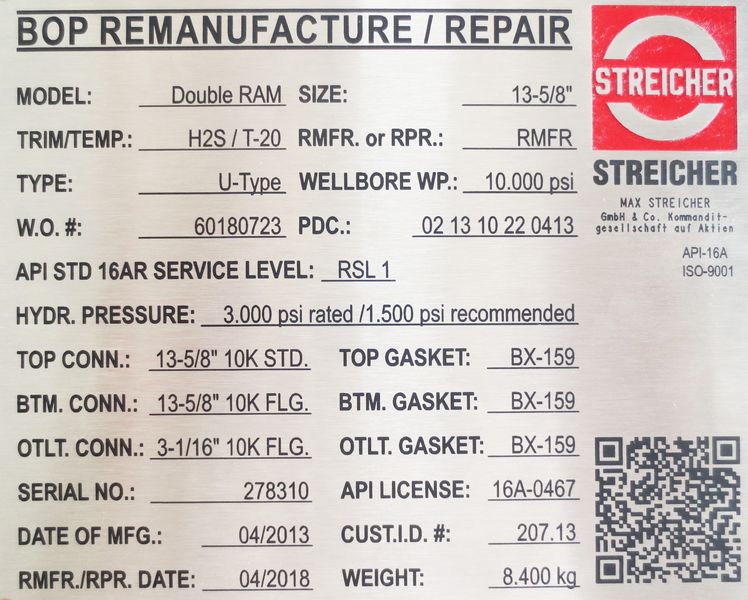

Well control equipment for offshore operations

We support our global operating customers with re-certification, repair, upgrade, new build and rental of well control equipment. As an American Petroleum Institute (API) Spec 16 A and API Spec 16D certified facility, we support, together with our partners, the re-certification of all major types and manufacturers.

Our offshore-certified staff supports offshore operations worldwide. With the help of our network and partners, we are a partner for urgent requests on rental and purchases.

About STREICHER

STREICHER Drilling Technology is a member of the STREICHER Group. The STREICHER Group supports its clients with more than 3,500 employees at 30 locations worldwide.