REMA Division is part of REMAZEL Engineering. The company was created when Zambetti e Lumina and Rema Engineering merged in 2010.

REMA has been operating in the offshore and oil and gas industry since 1990. It is well known as a solution provider with field-proven applications and for its products’ high level of reliability and performance.

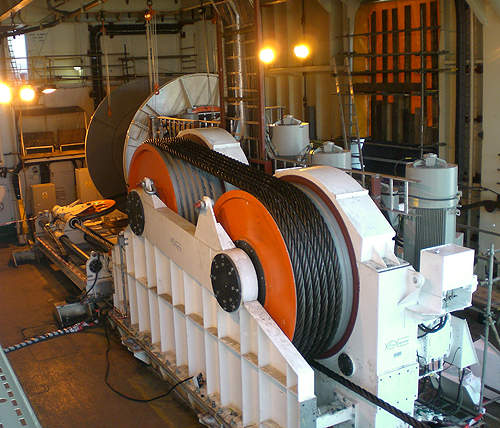

Mooring systems and winches for the offshore industry

REMA Division is a worldwide leader in design and fabrication of:

- Mooring systems for FPSOs

- A&R winches

- Traction / double capstans winches

- Storage winches

- Deepwater lowering / deployment winches

- Umbilical and flex pipe / hose reel winches

- Active heave compensated winches and AHC systems

- Linear winches

- Hawser winches

- Chain tensioners (chain jacks) for mooring and SCR pull-in (FPSO)

- Chain stoppers (deck mounted and hull mounted)

- Fairleads (underwater and above water)

- Combined underwater fairlead with chain stopper

- Sheaves and rope deviation systems

- Windlasses

- Pipe rollers for stingers

- Pipe laying and pipe handling systems

- Offloading systems

- Electric, diesel and hydraulic power units

- Local and remote controls

Reliable and high-quality offshore equipment

REMAZEL is recognised as a leader designer and manufacturer of highly reliable and field-proven offshore equipment. Our design concepts incorporate the latest and innovative solutions combined with experience and feedback from operational teams onboard vessels.

With R&D activity, a team of highly experienced engineers and in-house mechanical, electrical and hydraulic design expertise, we provide a broad range of tailor-made / special solutions and heavy-duty equipment for the offshore market, capable of working in the most severe environments and conditions, and meeting the customers’ specific project requirements.

In order to ensure products’ performance, reliability and weight optimisation, 3D modelling and FEA analysis are carried out on a regular basis; equipment is fully tested prior to delivery in order to guarantee the expected performances.

Mooring systems and SCR pull-in equipment for FPSOs

REMAZEL designs, manufactures, tests and installs mooring and SCR pull-in equipment for FPSOs such as chain jacks, chain stoppers, fairleads, windlasses, electric / hydraulic winches and rope deviation sheave systems.

REMAZEL has also designed and manufactured sets of mooring winches complete with the most modern control systems and hydraulic power units (HPU). We highlight that many of the solutions provided by us for FPSO mooring have been patented and this enforces the concept of innovative design and special solutions which characterise REMAZEL.

Within the mooring systems, REMAZEL provides also fairleads, chain stoppers, chain jacks, windlasses and sheaves / wildcat systems. REMAZEL has also revised and upgraded existing mooring systems.

Heavy-duty and tailor-made winches

REMAZEL can provide several types of tailor-made winches and winch systems such as traction / double capstans winches, A&R winches, storage drums, flexible pipes and umbilicals (deepwater lay) winches, hose reels, hawser winches, etc.

Electric, diesel and hydraulic-driven power systems are available for our equipment, complete with local control consoles and radio remote systems, both for safe and hazardous areas.

Factory acceptance tests (FAT), static and dynamic load test, commissioning and site integration tests are performed on a regular basis on all our equipment.

All our winches can be certified by third parties and classification societies such as ABS, DNV, RINA, Bureau Veritas, Lloyd’s Register, etc.

Pipe laying and pipe handling equipment

REMAZEL has experience in the design and supply of field-proven systems for pipe laying and handling, from pipe storage to fire lines, for the following applications:

- Shallow water pipe laying systems (S-lay)

- Deep water pipe laying systems (J-lay)

- Flexible and cable laying systems (reel lay)

We can supply standalone equipment as well as turnkey systems, ranging from support to our customers from the early stages of the feasibility study to lay-out optimisation through a specific and tailor-made design and solution.

Equipment supplied includes hydraulic and electric traction and storage winches for pipe abandon and recovery, pipe rollers, complete roller systems for stingers, specific hydraulic jacks, as well as any other tailor-made solutions.

REMAZEL has also revised and upgraded existing stingers, adding automatic roller hydraulic adjustment systems.

ISO9001 quality assurance

REMAZEL has a certified quality system according to ISO9001 and all our products are designed and manufactured in accordance with the latest quality standards. REMA Division has been serving the offshore and oil and gas industry since the supply of its first equipment in 1992 and is well known as a solution provider.

REMAZEL has an integrated health and quality system (HQSE) certified according to ISO14001 and BS OHSAS 18001.