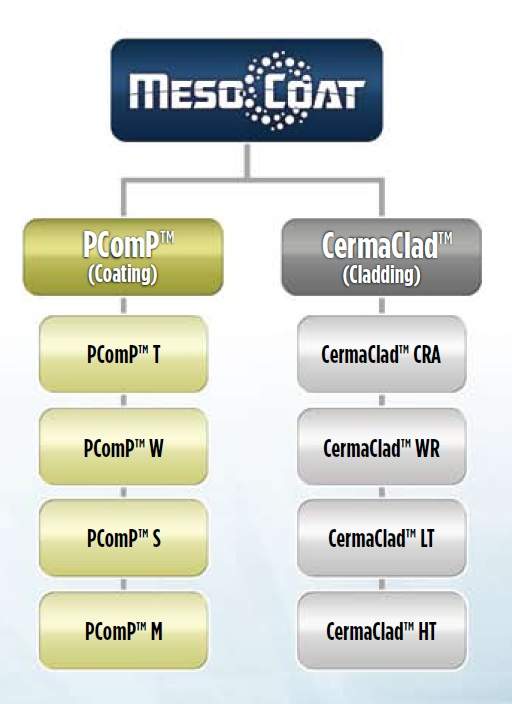

MesoCoat is a venture-backed nanotechnology materials science company which is fast becoming a world leader in metal protection and repair through its revolutionary high-speed cladding (CermaClad) and long-life coating (PComP) technologies.

The company’s transformational surface engineering technologies have received a number of R&D 100 awards along with several other industry innovation awards.

MesoCoat has developed high-strength, high-toughness ceramic-metallic materials and high-speed fusion cladding processes providing unparalleled wear and corrosion resistance.

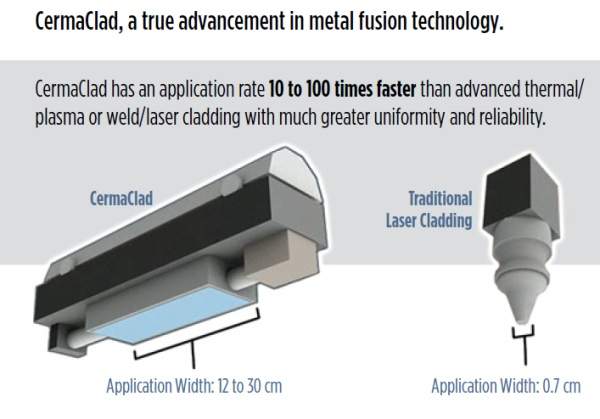

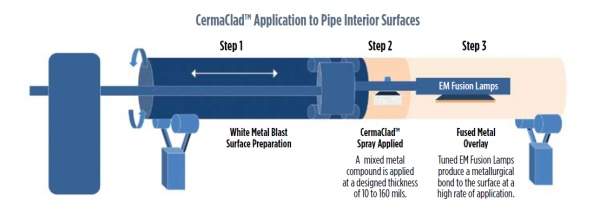

MesoCoat’s CermaClad technology uses a high-intensity light source (up to 500kW) to rapidly fuse protective, proprietary cladding materials on steel pipes and tubes (both internal and external surfaces), plates, sheets, and bars.

MesoCoat’s PComP nanocomposite metal-ceramic coatings offer the wear and corrosion resistance of ceramic materials such as diamond or glass, but with the toughness and resilience of metals.

These nanocomposite coatings replace current electrolytic hard chrome, electroplating, spray and fuse, physical and chemical vapour deposition, and thermal spray carbides to impart wear and corrosion resistance to metal surfaces, and reduce friction in sliding wear applications.

Corrosion-resistant (CRA) clad pipes

MesoCoat’s CermaClad CRA (corrosion resistant alloy) clad pipes are made from carbon steel pipes with a metallurgical cladding between 2mm-4mm. The result is a clad pipe that offers the same advantages as a solid alloy pipe at less than a quarter of the cost.

MesoCoat’s metallurgical clad pipes do not buckle under stress, unlike some mechanically lined pipes, and are approximately 20% cheaper than weld overlay clad pipes.

MesoCoat’s CermaClad CRA pipes can be used in deepwater offshore pipelines, risers, and flowlines along with several other onshore applications in oil and gas, petrochemical, desalination, power generation, and other industries.

The demand for CRA clad pipes is expected to grow, with over 80% of developing oil and gas fields demonstrating corrosive properties.

Wear resistant (WRA) clad pipes

MesoCoat’s CermaClad WRA (wear resistant alloy) clad pipes are made using proprietary wear-resistant materials including breakthrough semi-amorphous Metal (SAM) alloys and engineered cermet (ceramic-metal) composites like tungsten carbide (WC) and chrome carbide (CrC).

Depending on the application and life requirements, CermaClad WRA is applied at cladding thickness between 1mm to 15mm.

Carbon steel clad plates

MesoCoat CermaClad clad plates are made from carbon steel plates with a metallurgical cladding of proprietary corrosion and wear-resistant alloys.

Unlike other processes such as roll-bonding and explosion bonding, MesoCoat’s CermaClad clad plates can be made at very low thicknesses (100µ thin metallurgical cladding). Cladding on carbon steel plates is performed using MesoCoat’s revolutionary high-speed large-area fusion cladding technology that enables high productivity, true metallurgical bond and minimal dilution.

Clad plates are offered in a variety of metal, alloys, ceramic, and cermet combinations based on individual client specifications.

MesoCoat’s clad plates have extensive applications in nuclear, oil and gas, marine, desalination, petrochemical, power generation, and processing industries; where the clad plates are used to manufacture vessels, tanks, exchangers, and other large equipment and machinery.

Outer diameter (OD) clad pipes and tubes

MesoCoat offers outer diameter (OD) clad pipes and tubes in cladding thickness ranging from 100µ to 3mm.

The cladding on the pipes and tubes is applied using MesoCoat’s high-speed large-area fusion cladding technology, CermaClad, which enables high productivity, true metallurgical bond, minimal dilution, and can apply a variety of corrosion and wear-resistant materials on the OD of pipes and tubes.

MesoCoat’s CermaClad OD clad pipes and tubes have extensive applications in cross-country pipelines, under-insulation corrosion, boiler tubes and heat exchangers, and other applications in the petrochemical and processing industry.

Low thickness cost-effective metallurgical cladding

MesoCoat’s CermaClad LT (low thickness) solutions will provide corrosion resistance to steel components in salt water, atmospheric and environments, such as ballast and cargo tanks, LNG carriers and splash zone components.

CermaClad LT offers better protection than thermally sprayed materials, because its cladding is fully dense (no porosity), and metallurgically bonded to the base metal.

Component coatings and repair services

MesoCoat offers component coating and repair services using its proprietary nanoengineered cermet coating materials.

MesoCoat’s PComP coatings offer unparalleled performance at the lowest life cycle cost and have shown three times lower corrosion and up to 80 times lower wear in a variety of applications, when compared to other products.

MesoCoat currently offers the following four coating solutions for the oil and gas, mining, petrochemical, processing, and metals industries:

- PComP T-HT: high-toughness, corrosion-resistant nanostructured titanium cermet

- PComP T-HH: higher hardness, wear-resistant nanocomposite cermet with cobalt-based matrix

- PComP W: premium high-toughness nanoengineered WC-co cermet

- PComP S: lower density, low-spallation corrosion-resistant silicon nitride-based cermet