Integrated Global Services, Inc. (IGS) is an international turnkey provider of efficiency and reliability solutions.

Providing refineries with cutting-edge solutions to complex surface engineering issues

Boasting over three and a half decades of expertise, IGS has become a trusted partner to international plants, assisting them in addressing issues of metal wastage and reliability in mission-critical equipment.

IGS consists of operational hubs, subsidiaries, and sales offices globally to address the needs of global refining facilities. IGS is one of the top industry leaders in developing solutions to erosion and corrosion issues in difficult operational conditions.

IGS offers a variety of solutions that include:

High Velocity Thermal Spray (HVTS)

HVTS is a proprietary coating system designed to address corrosion and erosion problems in process vessels, towers, and columns. It is a time and cost-effective and reliable solution that extends equipment life.

Cetek Ceramic Coatings

Cetek Ceramic Coatings offers a versatile, durable, protective thin-film layer on the outer parts of tubes for the effective prevention of metal oxidation, corrosion, and carburisation and helps preserve the tube thermal conductivity coefficient close to new tube conditions.

Cetek ceramic coatings have been applied to more than 200 refining facilities globally, minimise fuel consumption, lower emissions, and boost production by enhancing fired heater radiant section efficiency.

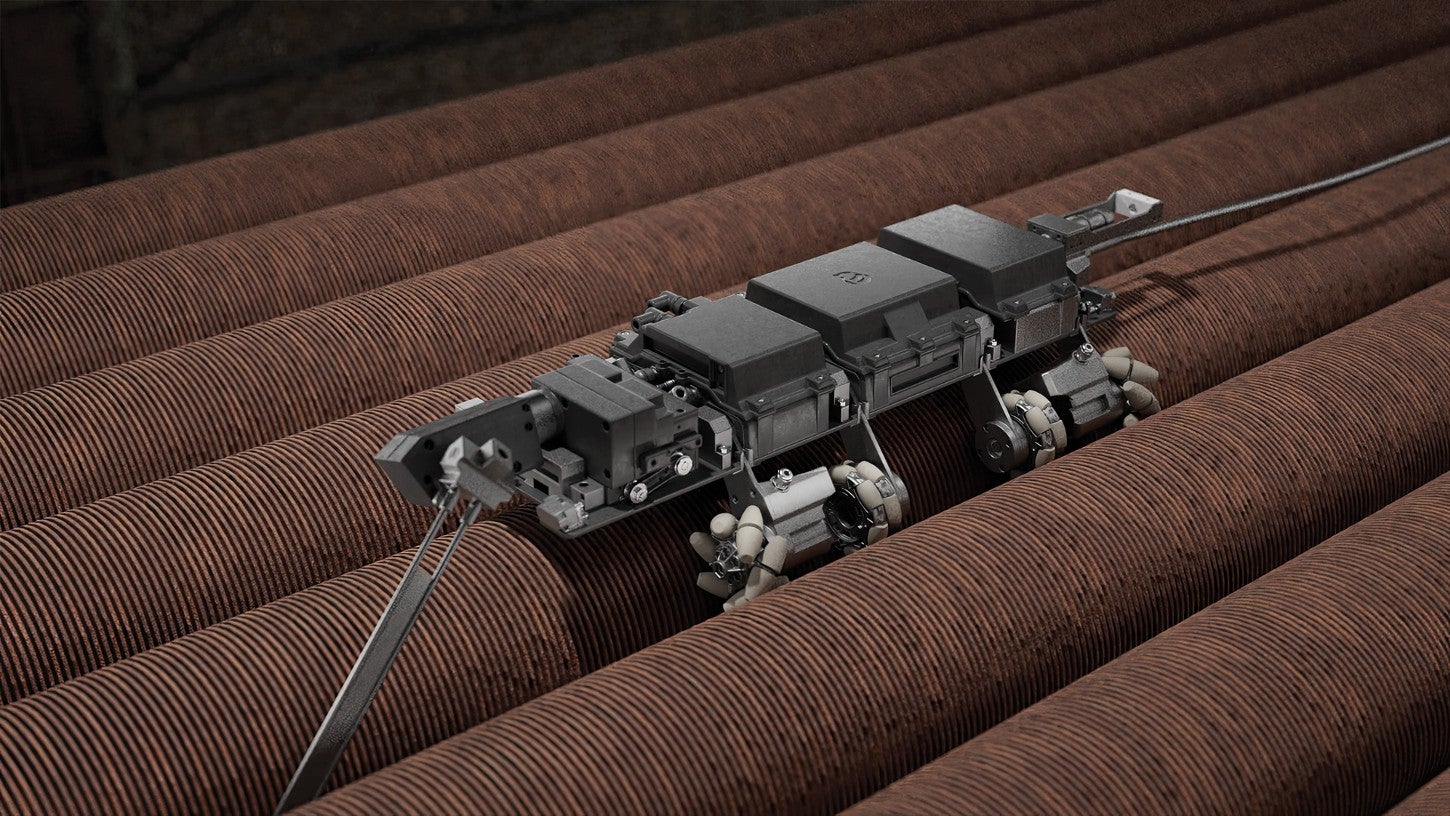

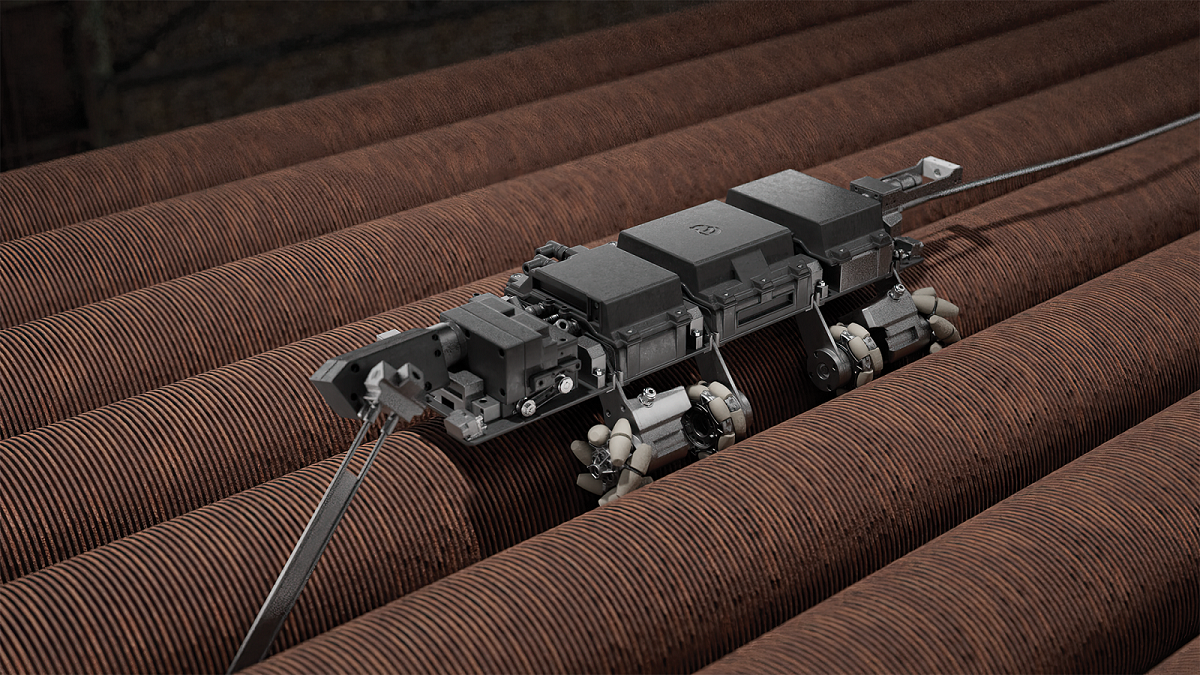

Tube Tech Fouling Removal

Tube Tech is popular due to its ability to solve the greatest fouling challenges worldwide. Tube Tech utilises its own technologies, including robotic systems, to remove over 90% of fouling from fired heater convection sections, heat exchanger bundles, Texas Towers (VCFEs), and a variety of other mission-critical assets.

By restoring heat transfer efficiency of the convection section, Tube Tech used in conjunction with Cetek ceramic coatings, Tube Tech can restore convection section heat transfer efficiency and can greatly enhance fired heater capacity, as well as lower CO2 and fuel consumption by up to 15% and reduce NOx emissions by up to 30%.

Hot-Tek

Hot-tek offers essential maintenance during normal operation (between turnarounds) to avoid unplanned shutdowns. These services consist of:

- Hot convection cleaning

- Hot tube descaling

- Hot refractory repair

- Hot vacuum service

- Hot inspection service

- Hot tube stabilisation

- Hot convection cleaning

- Hot tube descaling

- Hot refractory repair

- Hot vacuum service

- Hot inspection service

- Hot tube stabilisation

IGS is a specialist in global on-site technologies and exhibits a wide range of shop production capabilities. Its Technology Research Center helps the world’s leading refining facilities resolve their most critical surface engineering-related challenges, develop coating and welding techniques even further, and measure material performance.

With the largest global presence in the industry, IGS has the operational capacity and experience to provide solutions on-site across six different continents.

Integrated Global Services, Inc. (IGS) is an international turnkey provider of efficiency and reliability solutions.

Reliability and asset integrity

Our proprietary High-Velocity Thermal Spray (HVTS) coating systems solve corrosion and erosion problems in process vessels, towers and columns.

Efficiency, emissions reduction and decarbonisation

IGS utilises a variety of services for the improvement of fired heater efficiency when it comes to delivering increased capacity, up to 15% CO2/fuel reduction, and 30% less NOx. Cetek ceramic coatings boost radiant efficiency and increase throughput in fired heaters. Tube Tech services achieve a 90%-clean convection section while Environmental solutions enhance SCR efficiency and eliminate downtime.

IGS has one of the largest global footprints in the offshore industry, with operational capabilities and experience delivering solutions on-site on six continents.