The oil & gas industry continues to be a hotbed of patent innovation. Activity is driven by the need to innovate, improve efficiencies, increase safety, reduce environmental impact, and increasing competition, and the growing importance of technologies such as artificial intelligence (AI) and machine learning (ML), big data, blockchain, and robotics. In the last three years alone, there have been over 523,000 patents filed and granted in the oil & gas industry, according to GlobalData’s report on Internet of Things in oil & gas: intelligent predictive maintenance. Buy the report.

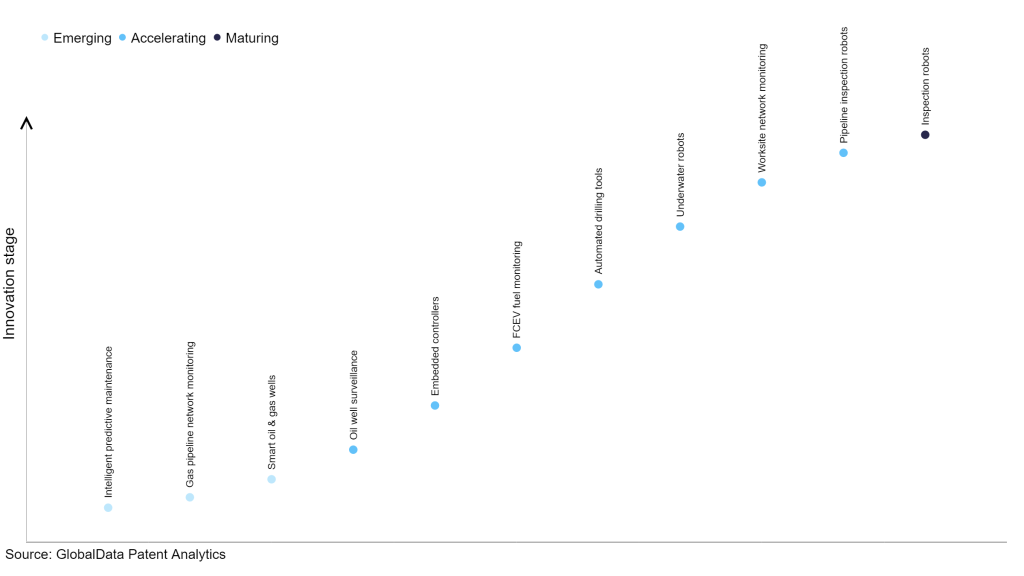

However, not all innovations are equal and nor do they follow a constant upward trend. Instead, their evolution takes the form of an S-shaped curve that reflects their typical lifecycle from early emergence to accelerating adoption, before finally stabilizing and reaching maturity.

Identifying where a particular innovation is on this journey, especially those that are in the emerging and accelerating stages, is essential for understanding their current level of adoption and the likely future trajectory and impact they will have.

60+ innovations will shape the oil & gas industry

According to GlobalData’s Technology Foresights, which plots the S-curve for the oil & gas industry using innovation intensity models built on over 196,000 patents, there are 60+ innovation areas that will shape the future of the industry.

Within the emerging innovation stage, intelligent predictive maintenance, gas pipeline network monitoring, and smart oil & gas wells are disruptive technologies that are in the early stages of application and should be tracked closely. Oil well surveillance, embedded controllers, and FCEV fuel monitoring are some of the accelerating innovation areas, where adoption has been steadily increasing. Among maturing innovation areas is inspection robots, which is now well established in the industry.

Innovation S-curve for Internet of Things in the oil & gas industry

Intelligent predictive maintenance is a key innovation area in Internet of Things

Intelligent predictive maintenance involves the use of AI and ML algorithms to predict and prevent equipment failure and downtime. It utilizes data from sensors and other sources to generate predictive models that can analyze the prevailing state of equipment and identify potential issues before they occur. The approach reduces maintenance costs and improves equipment reliability and availability.

GlobalData’s analysis also uncovers the companies at the forefront of each innovation area and assesses the potential reach and impact of their patenting activity across different applications and geographies. According to GlobalData, there are 50+ companies, spanning technology vendors, established oil & gas companies, and up-and-coming start-ups engaged in the development and application of intelligent predictive maintenance.

Key players in intelligent predictive maintenance – a disruptive innovation in the oil & gas industry

‘Application diversity’ measures the number of applications identified for each patent. It broadly splits companies into either ‘niche’ or ‘diversified’ innovators.

‘Geographic reach’ refers to the number of countries each patent is registered in. It reflects the breadth of geographic application intended, ranging from ‘global’ to ‘local’.

Patent volumes related to intelligent predictive maintenance

Source: GlobalData Patent Analytics

General Electric is one of the leading patent filers in intelligent predictive maintenance that uses IoT. It offers the Predix Platform, which is used by the company’s applications such as operations performance management (OPM) and asset performance management (APM) to optimize asset performance and enhance equipment efficiency. These applications essentially help to monitor asset health, diagnose industrial data for early problem detection, reduce the need for emergency repairs, and convert unplanned downtime into planned maintenance. For example, Saudi Aramco, a leading oil & and gas company, has integrated APM and Smart Signal into its IMOMS (Integrated Manufacturing Operations Management) solution. IMOMS employs commercial off-the-shelf technologies to enhance operational business processes effectively. Some other key patent filers in IoT-enabled intelligent predictive maintenance include Schlumberger and Halliburton.

In terms of application diversity, Hexagon Composites leads the pack, while Engie, and Cosmo Energy stood in the second and third positions, respectively. By means of geographic reach, Ecolab held the top position, followed by General Electric and Emerson Electric Co.

Oil and gas companies are increasingly using intelligent predictive maintenance tools that use IoT for enhancing reliability, optimizing efficiencies, and reducing operational costs.

To further understand the key themes and technologies disrupting the oil & gas industry, access GlobalData’s latest thematic research report on Internet of Things in Oil & Gas.

Premium Insights

From

The gold standard of business intelligence.

Blending expert knowledge with cutting-edge technology, GlobalData’s unrivalled proprietary data will enable you to decode what’s happening in your market. You can make better informed decisions and gain a future-proof advantage over your competitors.